Four-wheel Steering system

This paper deals with the

details of four wheel steering (4WS) system. With the help of this

system all the four wheels can be turned to any direction using the

steering. Thus the vehicle can be controlled more effectively especially

during cornering and parking. Also the speed of the vehicle can be

increased or decreased.

`There are three types of production of four-wheel ¬steering systems:

1. Mechanical 4WS

2. Hydraulic 4WS

3. Electro/hydraulic 4WS

`There are three types of production of four-wheel ¬steering systems:

1. Mechanical 4WS

2. Hydraulic 4WS

3. Electro/hydraulic 4WS

This system finds application in off-highway vehicles such as fork lifts, agricultural and construction equipment and mining machinery. It is also useful in passenger cars, mainly SUVs. Four-wheel steering, 4WS, also called rear-wheel steering or all-wheel steering, provides a means to actively steer the rear wheels during turning maneuvers. It should not be confused with four-wheel drive in which all four wheels of a vehicle are powered. It improves handling and help the vehicle make tighter turns.

Production-built cars tend to understeer or, in few instances, oversteer. If a car could automatically compensate for an understeer/oversteer problem, the driver would enjoy nearly neutral steering under varying conditions. 4WS is a serious effort on the part of automotive design engineers to provide near-neutral steering.The front wheels do most of the steering. Rear wheel turning is generally limited to 50-60 during an opposite direction turn. During a same direction turn, rear wheel steering is limited to about 10-1.50.

When both the front and rear wheels steer toward the same direction, they are said to be in-phase and this produces a kind of sideways movement of the car at low speeds. When the front and rear wheels are steered in opposite direction, this is called anti-phase, counter-phase or opposite-phase and it produces a sharper, tighter turn

Why Four-Wheel Steering System?:

To understand the advantages of four-wheel

steering, it is wise to review the dynamics of typical steering

maneuvers with a conventional front -steered vehicle. The tires are

subject to the forces of grip, momentum, and steering input when making a

movement other than straight-ahead driving. These forces compete with

each other during steering maneuvers. With a front-steered vehicle, the

rear end is always trying to catch up to the di¬rectional changes of the

front wheels. This causes the vehicle to sway. As a normal part of

operating a vehicle, the driver learns to adjust to these forces without

think¬ing about them.

When turning, the driver is putting into motion a com¬plex

series of forces. Each of these must be balanced against the others. The

tires are subjected to road grip and slip angle. Grip holds the car's

wheels to the road, and mo¬mentum moves the car straight ahead. Steering

input causes the front wheels to turn. The car momentarily resists the

turning motion, causing a tire slip angle to form. Once the vehicle

begins to respond to the steering input, cornering forces are generated.

The vehicle sways as the rear wheels attempt to keep up with the

cornering forces already generated by the front tires. This is referred

to as rear-end lag, because there is a time delay between steering input

and vehicle reaction. When the front wheels are turned back to a

straight -ahead position, the vehicle must again try to adjust by

reversing the same forces developed by the turn. As the steering is

turned, the vehicle body sways as the rear wheels again try to keep up

with the cornering forces generated by the front wheels.The idea behind four-wheel steering is that a vehicle requires less driver input for any steering maneuver if all four wheels are steering the vehicle. As with two-wheel steer vehicles, tire grip holds the four wheels on the road. However, when the driver turns the wheel slightly, all four wheels react to the steering input, causing slip angles to form at all four wheels. The entire vehicle moves in one direction rather than the rear half attempting to catch up to the front. There is also less sway when the wheels are turned back to a straight-ahead position. The vehicle responds more quickly to steering input because rear wheel lag is eliminated.

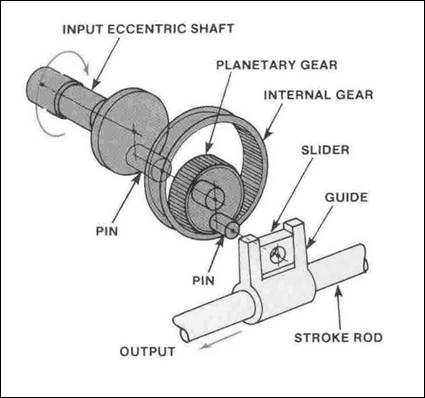

Mechanical 4WS

The planetary gear meshes with the matching teeth of an internal gear that is secured in a fixed position to the gearbox housing. This means that the planetary gear can rotate but the internal gear cannot. The eccentric pin of the planetary gear fits into a hole in a slider for the steer¬ing gear.

A 120-degree turn of the steering wheel rotates the planetary gear to move the slider in the same direction that the front wheels are headed. Proportionately, the rear wheels turn the steering wheel about 1.5 to 10 degrees. Further rotation of the steering wheel, past the 120¬degree point, causes the rear wheels to start straighten¬ing out due to the double-crank action (two eccentric pins) and rotation of the planetary gear. Turning the steer¬ing wheel to a greater angle, about 230 degrees, finds the rear wheels in a neutral position regarding the front wheels. Further rotation of the steering wheel results in the rear wheels going counter phase with regard to the front wheels. About 5.3 degrees maximum counter phase rear steering is possible.

Mechanical 4WS is steering angle sensitive. It is not sensitive to vehicle road speed.

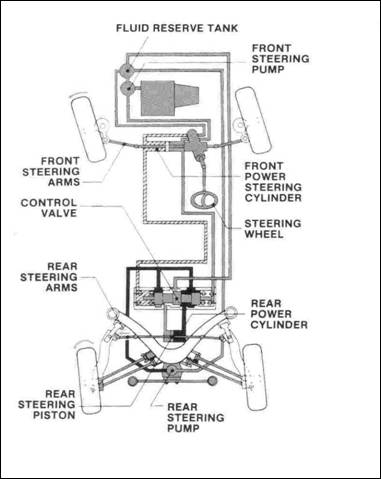

Hydraulic 4WS

The hydraulically operated four-wheel-steering system is a simple design, both in com¬ponents and operation. The rear wheels turn only in the same direction as the front wheels. They also turn no more than 11/2 degrees. The system only activates at speeds above 30 mph (50 km/h) and does not operate when the vehicle moves in reverse.

A two-way hydraulic cylinder mounted on the rear stub frame turn the wheels. Fluid for this cylinder is sup¬plied by a rear steering pump that is driven by the differ¬ential. The pump only operates when the front wheels are turning. A tank in the engine compartment supplies the rear steering pump with fluid.

When the steering wheel is turned, the front steering pump sends fluid under pressure to the rotary valve in the front rack and pinion unit. This forces fluid into the front power cylinder, and the front wheels turn in the direction steered. The fluid pressure varies with the turning of the steering wheel. The faster and farther the steering wheel is turned, the greater the fluid pressure.

The fluid is also fed under the same pressure to the control valve where it opens a spool valve in the control valve housing. As the spool valve moves, it allows fluid from the rear steering pump to move through and operate the rear power cylinder. The higher the pressure on the spool, the farther it moves. The farther it moves, the more fluid it allows through to move the rear wheels. As mentioned earlier, this system limits rear wheel movement to 11/2 degrees in either the left or right direction.

No comments:

Post a Comment